Ask our laser experts

Air Products' metal fabrication experts are here to help

Air Products' metal fabrication experts are here to help

Applications Engineer

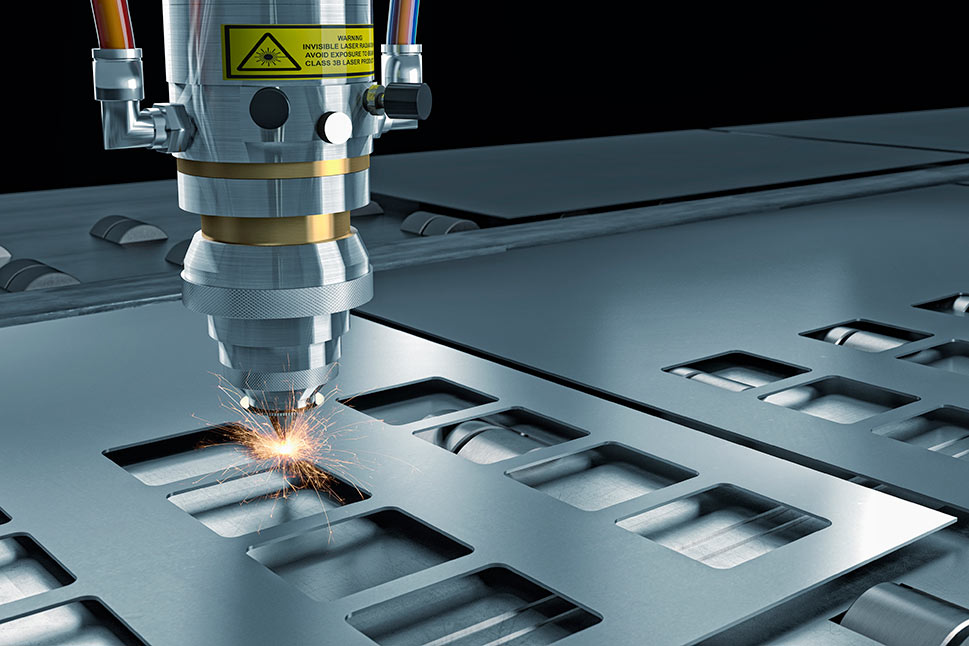

When laser cutting metals, a cutting gas is used, which flows out of the nozzle. The cutting gas not only protects the lens from fumes and spatter, it also cools the edges of the kerf, blows away molten metal and oxides from the kerf. And if oxygen is used, it also contributes to the cutting process by reacting with the metal to be cut. In laser oxygen cutting, the additional heat input from the oxidization of the metal is used to obtain high cutting speeds or to cut thicker material. This process fits only with mild steel and low-alloyed steel.

Gases used:

Each gas has unique properties which make it the preferred assist gas for cutting each of the material groups.

Useful as a gas, for its inert properties, and as a liquid for cooling and freezing. Virtually any industry can benefit from its unique properties to improve yields, optimize performance and make operations safer.

In addition to its use as a respiratory gas for healthcare applications, its strong oxidizing properties benefit many industries by improving yields, optimizing performance, lowering costs and reducing carbon footprint compared to other fuels.

Compressed argon gas and liquid argon in a variety of purities and in various modes of supply around the world thanks to our network of storage and transfill facilities.

An inert gas for cryogenic, heat transfer, shielding, leak detection, analytical and lifting applications

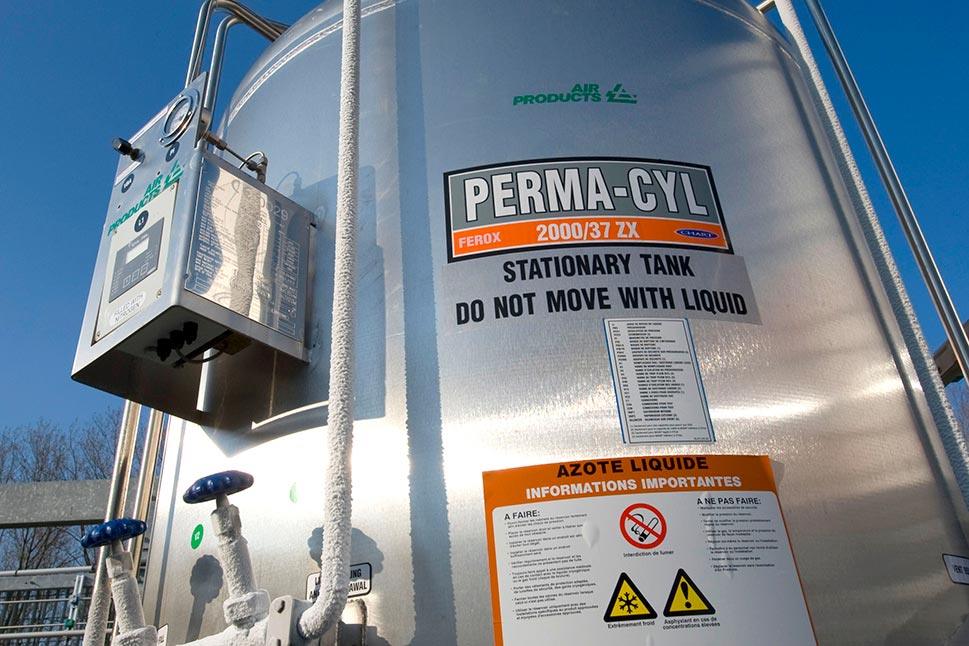

A convenient and cost-effective solution for larger operations. CryoEase® tanks are available in a range of sizes. The CryoEase® service simplifies your gas supply by eliminating the need to handle cylinders, stock taking and ordering.

Request a quote for your assist gases: nitrogen, oxygen, argon, helium or mixtures.

A compact on-site cryogenic tank that is regularly replenished by a specially-designed delivery vehicle. Air Products' CryoEase® microbulk service offers the advantages of bulk supply to smaller volume users of oxygen and nitrogen users.

Constant and reliable supply with a lower carbon footprint— you can reduce the number of gas deliveries to your business since Air Products looks after your order planning, fulfillment and delivery.