PRISM ® Cryogenic Nitrogen Process Overview

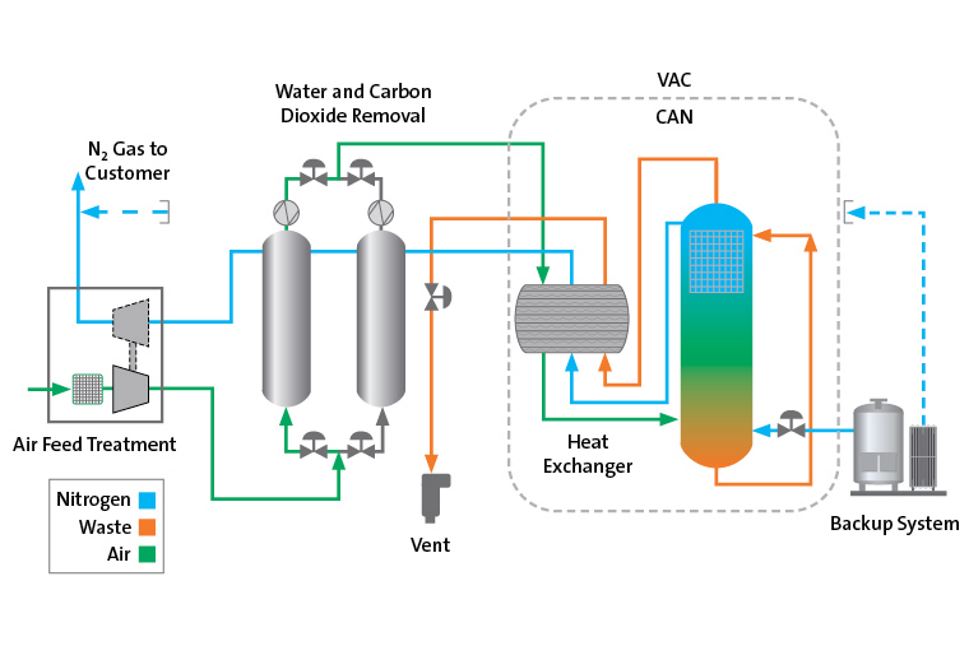

In a cryogenic air separation system, an atmospheric air feed is compressed and cooled to remove water vapor, carbon dioxide, and hydrocarbons before it enters the vacuum can, where a distillation column separates the air into nitrogen gas and an oxygen-enriched waste stream. The nitrogen gas then flows into the supply line to downstream applications where the product may be compressed to meet pressure requirements.

Cryogenic nitrogen plants can supply high-purity gas at rates less than 25,000 standard cubic feet per hour (scfh) to more than 2 million scfh. They typically achieve standard purities of 5 ppm oxygen in nitrogen, although higher purities are possible.

Discover Air Products Prism® Gas Generation

Interested in on-site gas plants and services?

Tell us about your needs and an on-site generated gas expert will contact you.