Ask the Expert

Jason Picard

Welding and Metal Fabrication Specialist

Base material thickness is probably the most important variable. Welding on thicker materials requires more penetration; therefore, choosing the correct shielding gas mix and wire is critical.

- For thicker weldments above 1/8”, 75/25 Ar/CO₂ with flux core wire or 90/10 metal core wire can improve penetration.

- 75/25 flux core offers great versatility in all positions and is the most common in commercial production welding shops for structural weldments.

- 90/10 metal core makes the weld puddle soupy, more fluid, and harder to handle for vertical and overhead positions. However, it has great penetration for flat and horizontal on T and Butt Joints.

- 75/25 solid wire and short circuit transfer is typical when welding on 1/8” material or less with the correct amperage and voltage. This allows for better control and welding can be done in all positions with less penetration above 1/8” weldments. The 75/25 gas mix works great for sheet metal, car body shops and thinner mild steel weldments.

Air Products offers a full range of standard shielding gases for MIG/MAG and TIG welding for all common material types. These are available in cryogenic liquid vessel sizes to meet all of your welding needs. Our unique range of shielding gases has been designed following rigorous testing under real working conditions. They offer the highest levels of performance to maximize your productivity, increase efficiency, reduce rejects, and improve your working environment. Contact us and our experienced applications team will use their knowledge of your industry and application to provide you with a supply of welding gases and a technology solution to meet your unique needs.

See the Benefits of our Maxx® Gases Range

Air Products’ Gastrak® Service

Save money, increase productivity and improve quality.

- Reduce costs: By eliminating pre-weld surge and excessive gas flow rates you will use less gas.

- Improve quality: Consistent use of the optimum gas flow rate improves weld quality and reduces rejects.

- Easy installation: Gastrak® equipment can be integrated into an existing or new gas pipeline.

Related Industries

Air Products offers thousands of products and services to a variety of different industries. This scope and experience has enabled us to develop a deeper understanding of the demands of these industries, and of your particular needs.

We have provided information most relevant to you within this industry section, but you may find information in other related industries of interest as well. The attached list is provided as a convenience for you or you can click on “Industries” in the top navigation for a full listing.

Gases and Supply Options

Argon

Compressed argon gas and liquid argon in a variety of purities and in various modes of supply around the world thanks to our network of storage and transfill facilities.

Carbon Dioxide

Our experienced applications teams across the globe can use their industry and application knowledge to provide you with a compressed or liquid carbon dioxide supply and technology solution to meet your unique needs.

Nitrogen

Useful as a gas, for its inert properties, and as a liquid for cooling and freezing. Virtually any industry can benefit from its unique properties to improve yields, optimize performance and make operations safer.

Oxygen

In addition to its use as a respiratory gas for healthcare applications, its strong oxidizing properties benefit many industries by improving yields, optimizing performance, lowering costs and reducing carbon footprint compared to other fuels.

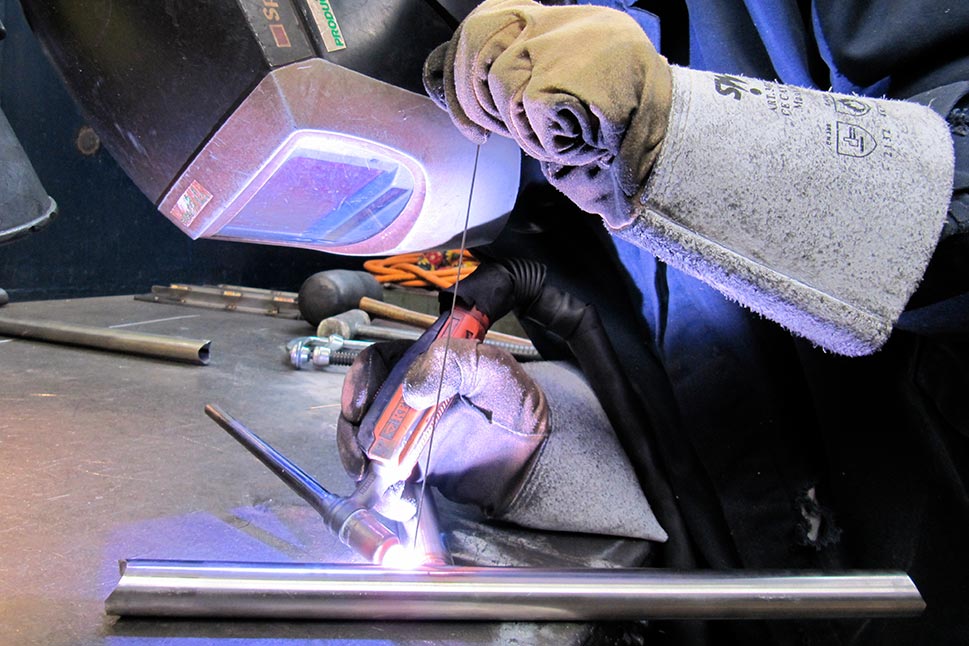

Welding Cutting Gases

A range of gases, technologies and services for metal fabrication, whether you are welding, cutting, thermal spraying, brazing or gouging.

Resource Center

Data Sheets

Data Sheets

Brochures

- Maxx® Weld Process Gases

- Nitrogen Supply Systems for High-Pressure Laser- Assist Gas

- LaserPak, High Pressure, High Flow Portable Assist-Gas System

- CryoEase microbulk solutions standard outdoor installation…

- CryoEase® Microbulk Solutions: A Cost-effective Alternative to Cylinder Supply

- Optimizing Gas Supply for Industrial Lasers