Ask the Expert

“Can I reduce the smell when welding stainless steel?”

A lot of the smell comes from ozone. Using Inomaxx® TIG gas reduces ozone from 0.013 ppm to only 0.001 ppm - an amazing reduction of over 90%.

See the Benefits of Our Welding Gases

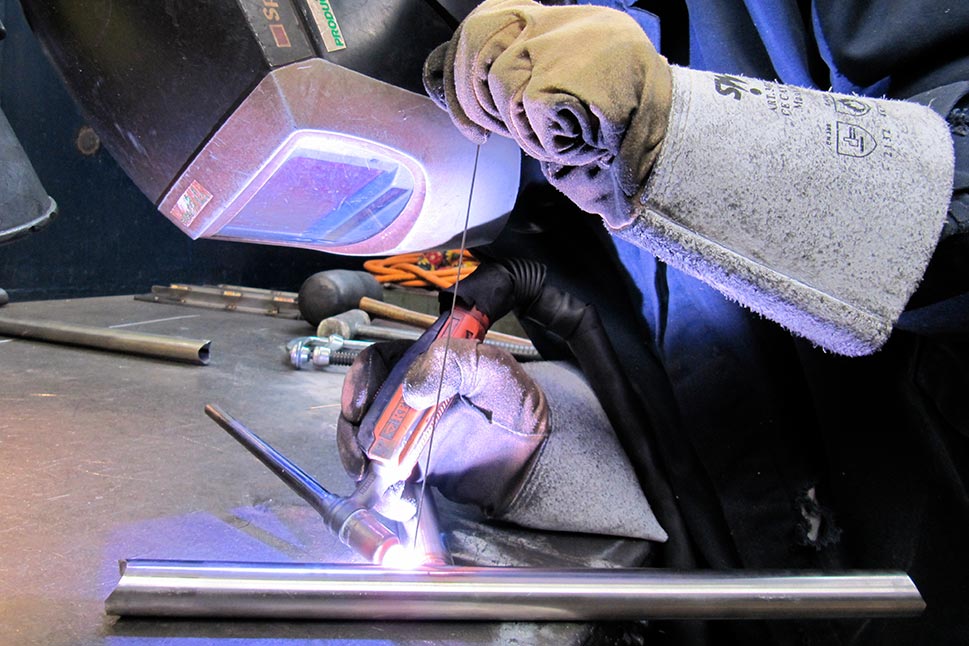

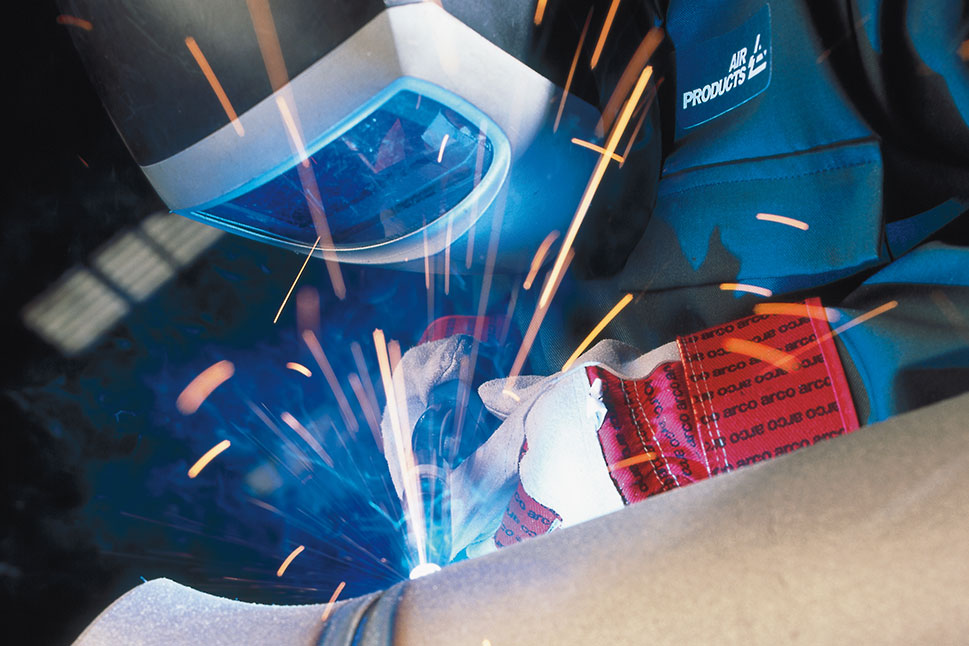

Whatever you’re welding, Air Products’ innovative range of welding gases will give you superior results. Formulated to boost output through a unique combination of weldability, weld quality and higher welding speeds, you’ll achieve more with fewer rejects.

Seeing is believing: book a demo

Seeing is believing:

Get expert advice and experience our specialist gases for welding aluminum and its alloys at your site.

See the Benefits of our Maxx® Gases Range

Whatever you’re welding, Air Products’ innovative range of welding gases will give you superior results. Formulated to boost output through a unique combination of weldability, weld quality and higher welding speeds, you’ll achieve more with fewer rejects.

Air Products’ Gastrak® Service

Save money, increase productivity and improve quality.

- Reduce costs: By eliminating pre-weld surge and excessive gas flow rates you will use less gas.

- Improve quality: Consistent use of the optimum gas flow rate improves weld quality and reduces rejects.

- Easy installation: Gastrak® equipment can be integrated into an existing or new gas pipeline.

RESOURCE CENTER

Data Sheets

Data Sheets

Brochures

- Maxx® Weld Process Gases

- Nitrogen Supply Systems for High-Pressure Laser- Assist Gas

- LaserPak, High Pressure, High Flow Portable Assist-Gas System

- CryoEase microbulk solutions standard outdoor installation…

- CryoEase® Microbulk Solutions: A Cost-effective Alternative to Cylinder Supply

- Optimizing Gas Supply for Industrial Lasers