Argon

Compressed argon gas and liquid argon in a variety of purities and in various modes of supply around the world thanks to our network of storage and transfill facilities.

Microbulk Applications Engineer, North America

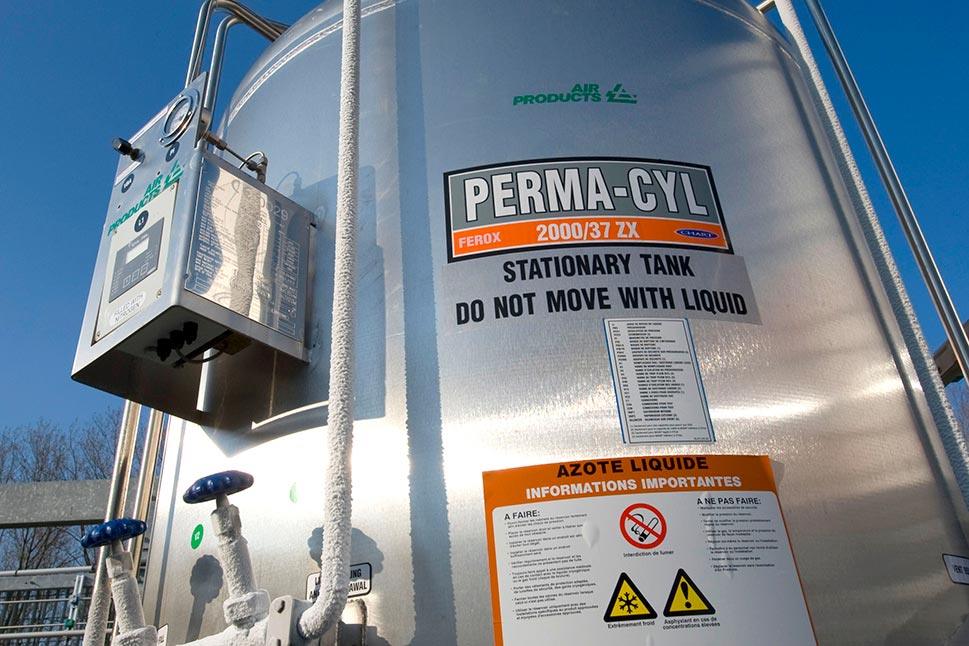

A compact on-site cryogenic tank that is regularly replenished by a specially-designed delivery vehicle. Air Products' CryoEase® microbulk service offers the advantages of bulk supply to smaller volume users of oxygen and nitrogen users.

Constant and reliable supply with a lower carbon footprint— you can reduce the number of gas deliveries to your business since Air Products looks after your order planning, fulfillment and delivery.

Compressed argon gas and liquid argon in a variety of purities and in various modes of supply around the world thanks to our network of storage and transfill facilities.

An inert gas for cryogenic, heat transfer, shielding, leak detection, analytical and lifting applications

Valued for its reactive and protective properties, and used by many industries such as electronics, foods, glass, chemicals, refining and more can benefit from its unique properties to improve quality, optimize performance and reduce costs.

Useful as a gas, for its inert properties, and as a liquid for cooling and freezing. Virtually any industry can benefit from its unique properties to improve yields, optimize performance and make operations safer.

In addition to its use as a respiratory gas for healthcare applications, its strong oxidizing properties benefit many industries by improving yields, optimizing performance, lowering costs and reducing carbon footprint compared to other fuels.

Contact us to put decades of experience with industrial gases, production, application and equipment to work for you.