Speak to our MetFab cutting experts.

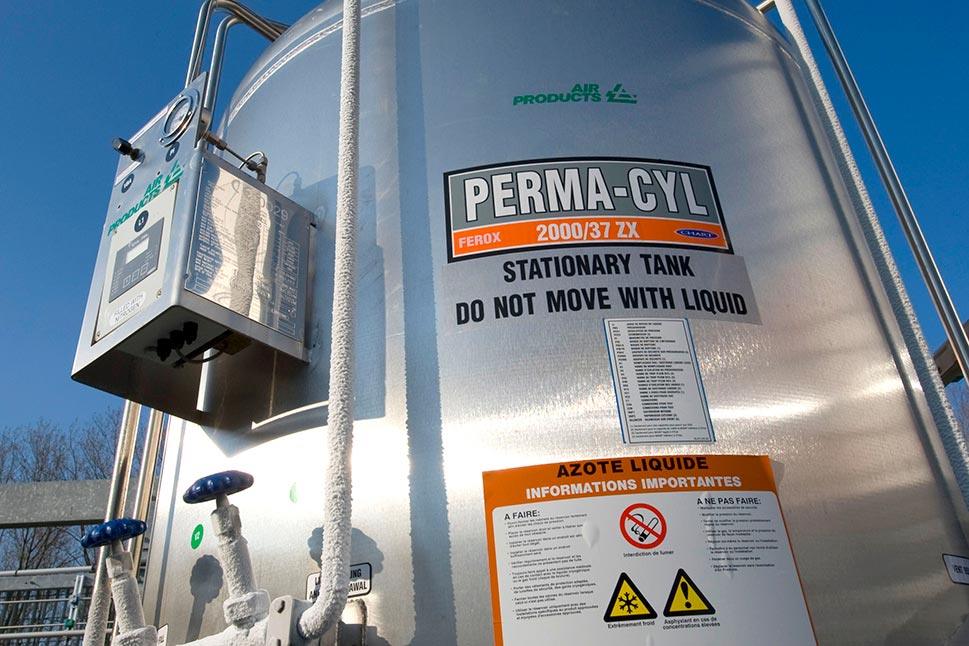

CryoEase® Microbulk Solutions – Gas Supply Made Simple

A compact on-site cryogenic tank that is regularly replenished by a specially-designed delivery vehicle. Air Products' CryoEase® microbulk service offers the advantages of bulk supply to smaller volume users of oxygen and nitrogen users.

- Saves time – no more handling or changing of cylinders

- Saves space – tank can be sited conveniently to relieve valuable floor space

- Peace of mind – our Gas Management system automatically schedules regular deliveries, saving you the hassle of chasing orders or waiting for deliveries

Constant and reliable supply with a lower carbon footprint— you can reduce the number of gas deliveries to your business since Air Products looks after your order planning, fulfillment and delivery.

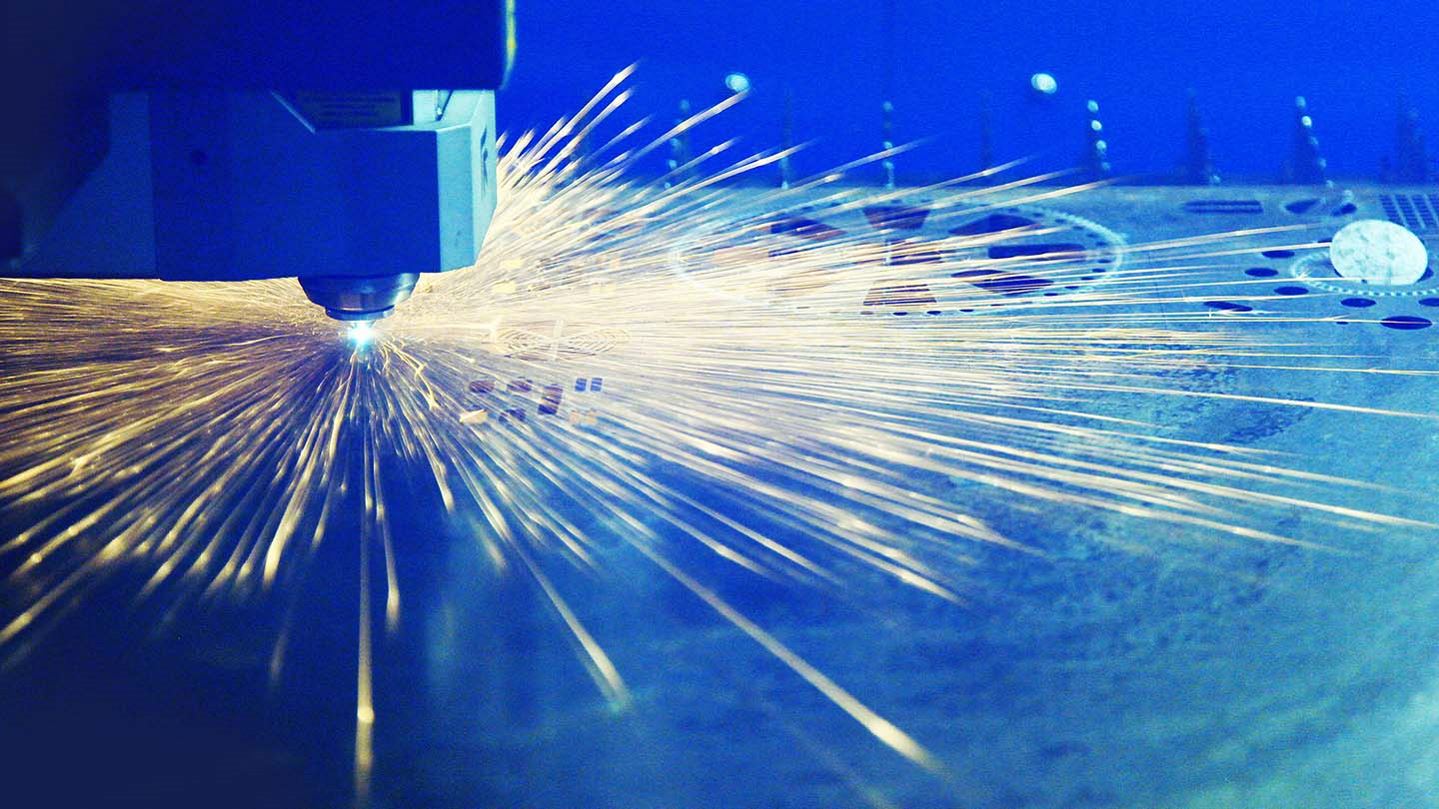

Optimizing your laser cutting gas supply

In cutting, it is not the preheat flame that performs the cutting operation, but rather an oxygen jet. This oxygen jet oxidizes the metal, with the evolution of heat, and expels the combustion products (the slag) from the kerf. The purpose of the preheat flame is to heat the metal to the ignition temperature, sustain the cutting process and support the cutting oxygen jet.

Hydrogen can be used as a fuel gas for e.g. gas cutting. Its flame temperature and flame intensity are lower than those of acetylene and many other gases, but higher than those of propane and natural gas.

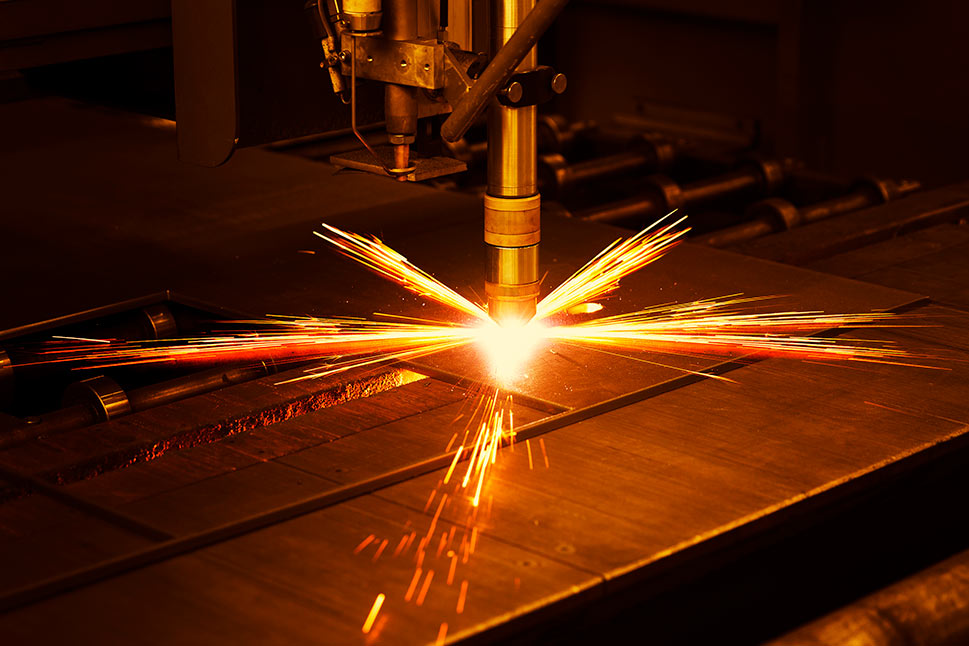

The selection of gas or gases for plasma arc cutting is based on such factors as the required quality of the cut, the thickness of metal to be cut and the gas cost. For cutting thin metal a single gas flow is often used to provide both the plasma and the arc shielding, but for cutting thicker metal, dual gas flows are used. The single gas flow may be air, nitrogen, nitrogen/hydrogen, oxygen or argon. The dual gas flows may be nitrogen, nitrogen/hydrogen, oxygen, argon or argon/hydrogen mixtures.

Ask the Expert

Don Bowe

Applications Engineer

A relatively small amount of impurities can make a big difference. Gas purity is often referred to in grades 3, 4, and 5. Grade 3 is 99.9% pure, 4 is 99.99 %, and 5 is 99.999%. Many OEM’s typically require grade 5, or five 9’s, purity. It is often more meaningful to talk about the impurity levels rather than overall purity. The main impurities of concern are oxygen and moisture, which can oxidize the material being cut. Most industrial liquid nitrogen grades meet the five 9’s purity level, meaning they contain less than .001%, or 10 PPM, of oxygen. Also, the dew point (moisture level) of gaseous nitrogen from a liquid nitrogen supply is typically less than –90°F, or less than 3 PPMV. Lower impurity levels result in less oxidization, yielding cleaner cut metals.

The impact of N₂ purity on the cleanliness of the laser cut is illustrated in the photos below. In this example, a bright, clean surface is achieved only with a nitrogen purity of at least 99.995%.

Let Air Products put our experience in laser applications to work for you. We provide total solutions for your laser cutting requirements with equipment, technology and reliable gas supply. We have the expertise that comes from being a leading supplier to the industry around the world.

Gas Supply Options

Bulk Supply

Delivered by truck and stored on your site either as a liquid in cryogenic tanks or as a gas in high-pressure tubes based on your volume, desired pressure, purity level, flow rate, and operating pattern.

CryoEase® Microbulk Solutions

A convenient and cost-effective solution for larger operations. CryoEase® tanks are available in a range of sizes. The CryoEase® service simplifies your gas supply by eliminating the need to handle cylinders, stock taking and ordering.

Hydrogen

Valued for its reactive and protective properties, and used by many industries such as electronics, foods, glass, chemicals, refining and more can benefit from its unique properties to improve quality, optimize performance and reduce costs.

Nitrogen

Useful as a gas, for its inert properties, and as a liquid for cooling and freezing. Virtually any industry can benefit from its unique properties to improve yields, optimize performance and make operations safer.

Oxygen

In addition to its use as a respiratory gas for healthcare applications, its strong oxidizing properties benefit many industries by improving yields, optimizing performance, lowering costs and reducing carbon footprint compared to other fuels.